Compressive strength performance of deep groove ball bearings:

1. Deep groove ball bearing clearance should be appropriate, too large impact, too small poor lubrication, may burn tile.

2. Improve lubrication quality, control oil pressure, temperature and flow (unit: cubic meters per second), strengthen oil filtration.

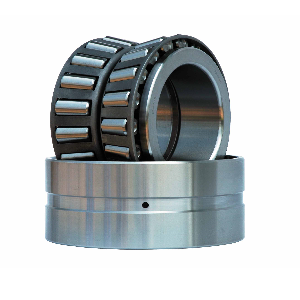

3. The surface quality and geometric shape of deep groove ball bearings and shaft diameters should be strictly and properly guaranteed. Tapered roller bearing is a kind of rolling bearing, which is widely used in modern machinery. It relies on the rolling contact between the main components to support the rotating parts. Roller bearings are now mostly standardized. Roller bearing has the advantages of small torque required for starting, high rotation accuracy and convenient selection.

4. Use fuel oil and lubricating oil conforming to the designation.

5. It is unfavorable to control the temperature state of diesel engine under the condition of undercooling and overheating. In cold weather, the diesel engine should be preheated before starting, and the oil enters the friction surface by hand rolling the crankshaft.

The cleanliness of bearings has a great impact on the life of bearings. Bearing manufacturers have carried out special tests for this purpose, and the results are that the difference is several times or even dozens of times more. The higher the cleanliness of bearings, the longer the life of bearings and other tests show that different cleanliness of lubricating oil has a great impact on the life of ball bearings

Post time: Oct-08-2021