high quality plain thrust ball bearings

Bearing resolution

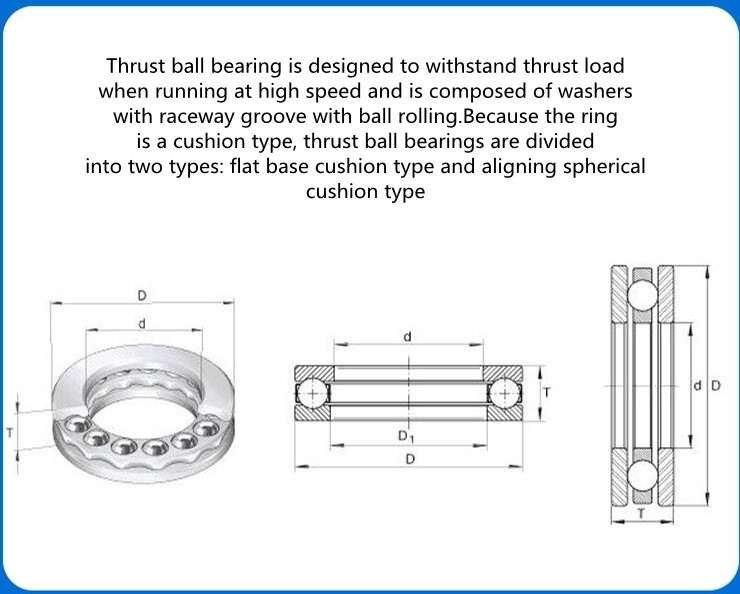

Thrust ball bearing is designed to withstand thrust load when running at high speed and is composed of washer-like rings with ball rolling raceway groove. Because the ring is in the shape of seat, thrust ball bearings are divided into two types: flat base cushion type and aligning spherical cushion type. In addition, these bearings can withstand axial loads but not radial loads.

6 quality points to watch

REALITY PATS SHOW

Our warehouse

TARGET-MARKET

Shipping

Application of our bearing

Thrust roller bearings can be used in many applications . Examples including mining equipment , oil production , steel production , smelting , and mining . Some spherical roller bearings are used in briquetting machines , rubber mixing equipment , rolling mills , rotary dryers or pulp and paper machinery . Others are used in construction equipment , crushers ,motors , blowers and fans , gears and drives , plastic machinery , machine tools , and traction motors and pumps.

Installation Instructions for Bearing

Parameters

| Bearing No. | Dimensions (mm) | Load Rating | Weight(KG) | |||||||||||||||

| 51000 | 53000 | 53000U | d | D | T | d1 | D1 | r | T2 | R | A | T3 | d3 | D3 | C | Cr | Cor | |

| 51100 | - | - | 10 | 24 | 9 | 11 | 24 | 0.3 | - | - | - | - | - | - | - | 10 | 14 | 0.02 |

| 51200 | 53200 | 53200U | 26 | 11 | 12 | 26 | 0.6 | 11.6 | 22 | 8.5 | 13 | 18 | 28 | 3.5 | 12.7 | 17.1 | 0.03 | |

| 51101 | - | - | 12 | 26 | 9 | 13 | 26 | 0.3 | - | - | - | - | - | - | - | 10.3 | 15.4 | 0.022 |

| 51201 | 53201 | 53201U | 28 | 11 | 14 | 28 | 0.6 | 11.4 | 25 | 11.5 | 13 | 20 | 30 | 3.5 | 13.2 | 19 | 0.034 | |

| 51102 | - | - | 15 | 28 | 9 | 16 | 28 | 0.3 | - | - | - | - | - | - | - | 10.5 | 16.8 | 0.024 |

| 51202 | 53202 | 53202U | 32 | 12 | 17 | 32 | 0.6 | 13.3 | 28 | 12 | 15 | 24 | 35 | 4 | 16.6 | 24.8 | 0.046 | |

| 51103 | - | - | 17 | 30 | 9 | 18 | 30 | 0.3 | - | - | - | - | - | - | - | 10.8 | 18.2 | 0.028 |

| 51203 | 53203 | 53203U | 35 | 12 | 19 | 35 | 0.6 | 13.2 | 32 | 16 | 15 | 26 | 38 | 4 | 17.1 | 27.3 | 0.053 | |

| 51104 | - | - | 20 | 35 | 10 | 21 | 35 | 0.3 | - | - | - | - | - | - | - | 14.3 | 24.7 | 0.04 |

| 51204 | 53204 | 53204U | 40 | 14 | 22 | 40 | 0.6 | 14.7 | 36 | 18 | 17 | 30 | 42 | 5 | 22.2 | 37.5 | 0.082 | |

| 51304 | - | - | 47 | 18 | 22 | 47 | 1 | - | - | - | - | - | - | - | 28.3 | 46.8 | 0.015 | |

| 51105 | - | - | 25 | 42 | 11 | 26 | 42 | 0.6 | - | - | - | - | - | - | - | 19.5 | 37 | 0.059 |

| 51205 | 53205 | 53205U | 47 | 15 | 27 | 47 | 0.6 | 16.7 | 40 | 19 | 19 | 36 | 50 | 5.5 | 27.8 | 50.5 | 0.12 | |

| 51305 | 53305 | 53305U | 52 | 18 | 27 | 52 | 1 | 19.8 | 45 | 21 | 22 | 38 | 55 | 6 | 35.5 | 61.5 | 0.18 | |

| 51405 | 53405 | 53405U | 60 | 24 | 27 | 60 | 1 | 26.4 | 50 | 19 | 29 | 42 | 62 | 8 | 55.5 | 89.5 | 0.34 | |

| 51106 | - | - | 30 | 47 | 11 | 32 | 47 | 0.6 | - | - | - | - | - | - | - | 20.4 | 42 | 0.068 |

| 51206 | 53206 | 53206U | 52 | 16 | 32 | 52 | 0.6 | 17.8 | 45 | 22 | 20 | 42 | 55 | 5.5 | 29.3 | 58 | 0.15 | |

| 51306 | 53306 | 53306U | 60 | 21 | 32 | 60 | 1 | 22.6 | 50 | 22 | 25 | 45 | 62 | 7 | 42.5 | 78.5 | 0.27 | |

| 51406 | 53406 | 53406U | 70 | 28 | 32 | 70 | 1 | 30.1 | 56 | 20 | 33 | 50 | 75 | 9 | 72.5 | 126 | 0.53 | |

| 51107 | - | - | 35 | 52 | 12 | 37 | 52 | 0.6 | - | - | - | - | - | - | - | 20.4 | 44.5 | 0.085 |

| 51207 | 53207 | 53207U | 62 | 18 | 37 | 62 | 1 | 19.9 | 50 | 24 | 22 | 48 | 65 | 7 | 39 | 78 | 0.22 | |

| 51307 | 53307 | 53307U | 68 | 24 | 37 | 68 | 1 | 25.6 | 56 | 24 | 28 | 52 | 72 | 7.5 | 55.5 | 105 | 0.39 | |

| 51407 | 53407 | 53407U | 80 | 32 | 37 | 80 | 1.1 | 34 | 64 | 23 | 37 | 58 | 85 | 10 | 87 | 155 | 0.79 | |

| 51108 | - | - | 40 | 60 | 13 | 42 | 60 | 0.6 | - | - | - | - | - | - | - | 26.9 | 63 | 0.12 |

| 51208 | 53208 | 53208U | 68 | 19 | 42 | 68 | 1 | 20.3 | 56 | 28.5 | 23 | 55 | 72 | 7 | 47 | 98.5 | 0.27 | |

| 51308 | 53308 | 53308U | 78 | 26 | 42 | 78 | 1 | 28.5 | 64 | 28 | 31 | 60 | 82 | 8.5 | 69 | 135 | 0.55 | |

| 51408 | 53408 | 53408U | 90 | 36 | 42 | 90 | 1.1 | 38.2 | 72 | 26 | 42 | 65 | 95 | 12 | 112 | 205 | 1.14 | |

| 51109 | - | - | 45 | 65 | 14 | 47 | 65 | 0.6 | - | - | - | - | - | - | - | 27.8 | 69 | 0.15 |

| 51209 | 53209 | 53209U | 73 | 20 | 47 | 73 | 1 | 21.3 | 56 | 26 | 24 | 60 | 78 | 7.5 | 47.5 | 105 | 0.32 | |

| 51309 | 53309 | 53309U | 85 | 28 | 47 | 85 | 1 | 30.1 | 64 | 25 | 33 | 65 | 90 | 10 | 80 | 163 | 0.69 | |

| 51409 | 53409 | 53409U | 100 | 39 | 47 | 100 | 1.1 | 42.4 | 80 | 29 | 46 | 72 | 105 | 12.5 | 129 | 243 | 1.47 | |