Leading Manufacturer for Deep Groove Ball Bearing Rubber - Stainless Steel Deep Groove Ball Bearings – XINRI

Leading Manufacturer for Deep Groove Ball Bearing Rubber - Stainless Steel Deep Groove Ball Bearings – XINRI Detail:

Introduction

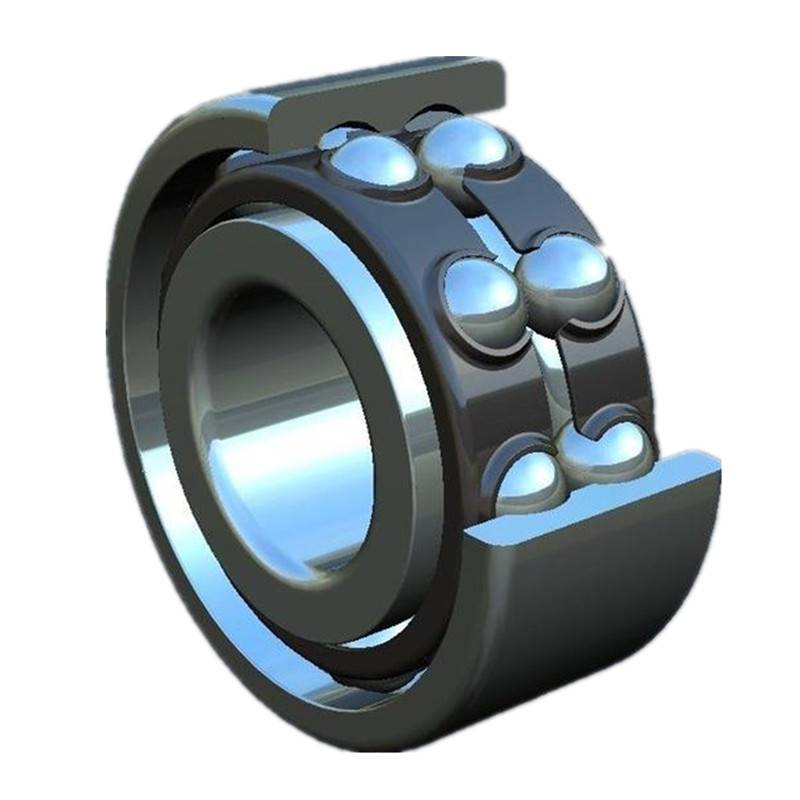

Stainless steel deep groove ball bearings are corrosion resistant when exposed to moisture and several other media. They are available capped (with seals or shields) or open. Open bearings that are also available capped may have recesses in the ring side faces. These bearings have a lower load carrying capacity than same-sized bearings made of high chromium steel.

Stainless steel bearings and ordinary bearings, not only on the material has obvious advantages, and in the process, precision control, more strict than ordinary bearings.

Features and Benefits

Stainless steel deep groove ball bearing because the material is stainless steel, so long service life, and not easy to rust, corrosion resistance and other characteristics. Stainless steel deep groove ball bearings mainly bear radial load, but also can bear radial load and axial load. When it only bears radial load, the contact Angle is zero. When the deep groove ball bearing has a large radial clearance, it has the performance of angular contact bearing and can bear a large axial load. The friction coefficient of the deep groove ball bearing is very small, and the limit speed is also very high.

Advantage

● Excellent corrosion resistance

● can be washable

● Can run in liquid

● The depletion rate is slower

● Sanitation

● High heat resistance

Application

Medical equipment, low temperature engineering, optical instruments, high speed machine tools, high speed motor, printing machinery, food processing machinery.

Stainless steel deep groove ball bearing usage is very big, application is extremely extensive, the factory that produces this kind of bearing is very common also, take this bearing as basic type more. Relatively speaking, the stainless steel deep groove ball bearing than other types of bearing movement friction coefficient is small, generally between 0.0015 and 0.0022, the use of friction Yang force is very small, while there is a higher rotation flexibility, more for the support of high-speed rotation axis.

Product detail pictures:

Related Product Guide:

Fast and fantastic quotations, informed advisers to help you choose the correct products that suits all your needs, a short manufacturing time, responsible good quality control and distinct companies for paying and shipping affairs for Leading Manufacturer for Deep Groove Ball Bearing Rubber - Stainless Steel Deep Groove Ball Bearings – XINRI , The product will supply to all over the world, such as: Spain, Chicago, Brasilia, By integrating manufacturing with foreign trade sectors, we can offer total customer solutions by guaranteeing the delivery of right items to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.