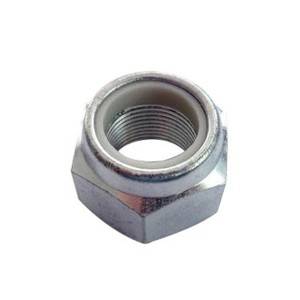

Lock Nuts

Introduction

Lock nuts are used to locate bearings onto a shaft. Additionally, they can be used to mount bearings with a tapered bore onto tapered shaft seats and adapter sleeves, and to dismount bearings from withdrawal sleeves. Lock nuts are also frequently used to secure gears, belt pulleys and other machine component.

Characteristics

●Play a stable locking function.

●Reduced axial force also prevents early shedding.

●All metal products, excellent heat and cold resistance.

●Simple tightening operation to prevent installation errors.

●Reusable.

Advantage

●The superior performance of vibration resistance: screw in the tight, bolt tooth top thread which affects tightly into the nut 30 ° cant wedge stuck tightly, and applied to wedge on the slope of the normal force and the axis of the bolts into 60 ° Angle, rather than 30 ° Angle, and therefore, tighten locknut when the normal force is greater than standard nut, has a great locking ability to resist vibration.

●Strong wear resistance and shear resistance: the 30° bevel of the bottom of the thread of the nut can make the locking force of the nut evenly distributed on the thread of all the teeth. Because of the uniform distribution of the compression force on the thread surface of each tooth, the nut can better solve the problems of thread wear and shear deformation.

●Sood reuse performance: extensive use shows that the locking force of the locknut is not reduced after repeated tightening and disassembly, and the original locking effect can be maintained.

A method of preventing loose nut from slipping

1. Mechanical loosing

2. Riveting anti-loose

3. Friction prevention

4. Build a pine barrier

5. Flush edge method to prevent loose