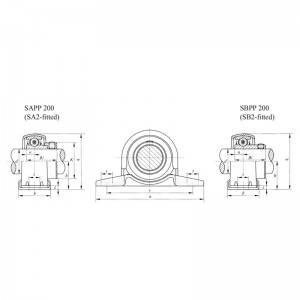

Precision insert bearing SAPP200 SBPP200

Introduction

Vertical stamping bearing pedestal, which is composed of steel plate stamping upper and lower shell, has the advantages of light weight and small volume compared with cast iron vertical pedestal, and is the type with the smallest installation space in vertical pedestal. But it can only be used in small loads.

Characteristics

1. Excellent anticorrosion performance.Roller body and seals are made of high polymer materials, corrosion resistant.When used in corrosive environment, the service life can reach more than 5 times of the ordinary roller.

2, wear resistance, long service life. High polymer material for roller body of idler, its mechanical property is similar to bronze, has good wear resistance, and has good self-lubricating property, and does not hurt the belt.

3. Reasonable structure and reliable sealing. The idler is provided with two seals, high precision in manufacturing, and special grease is applied in the gap, which can effectively prevent corrosive media such as dust, gas and liquid from entering the idler and damaging the bearing.

4. Light weight and small rotational inertia. The weight of the special polymer material for idlers is light, and its specific weight is one seventh of that of steel. The weight of idlers made of this material is about one half of that of ordinary idlers, with small rotational inertia and small friction between idlers and belts.

Application

SAPP SBPP applicable field: light load low speed machinery, light conveyor, etc

Parameters

| Bearing Unit | Shaft Dia. | Dimensions(in.)or (mm) | Bolt Used (in.) | SPAFL | SBPFL | Housing | |||||||||||||||||||||||||||

| d | |||||||||||||||||||||||||||||||||

| NO. | (in.) | (mm) | h | a | c | b | s | g(mm) | w | n | (mm) | Bi | K | Bearing No. | weight (kg) |

Bi | Bearing No. | weight (kg) |

NO. | ||||||||||||||

| SAPP SBPP |

201 | 12 | 7/8 | 3 | 3/8 | 2 | 43/64 | 63/64 | 3/8 | 1 | 23/32 | 0.2362 | 5/16 | 1.1220 | 1.1260 | SA | 201 | 0.8661 | SB | 201 | |||||||||||||

| 201-8 | 1/2 | 22.2 | 86 | 68 | 25 | 9.5 | 3.0 | 43.8 | 6.0 | M8 | 28.6 | 28.6 | 201-8 | 0.19 | 22 | 201-8 | 0.16 | PP | 201 | ||||||||||||||

| SAPP SBPP |

202 | 15 | 7/8 | 3 | 3/8 | 2 | 43/64 | 63/64 | 3/8 | 1 | 23/32 | 0.2362 | 5/16 | 1.1220 | 1.1260 | SA | 202 | 0.8661 | SB | 202 | |||||||||||||

| 202-10 | 5/8 | 22.2 | 86 | 68 | 25 | 9.5 | 3.0 | 43.8 | 6.0 | M8 | 28.6 | 28.6 | 202-10 | 0.19 | 22 | 202-10 | 0.16 | PP | 202 | ||||||||||||||

| SAPP SBPP |

203 | 17 | 7/8 | 3 | 3/8 | 2 | 43/64 | 63/64 | 3/8 | 1 | 23/32 | 0.2362 | 5/16 | 1.1220 | 1.1260 | SA | 203 | 0.8661 | SB | 203 | |||||||||||||

| 203-11 | 11/16 | 22.2 | 86 | 68 | 25 | 9.5 | 3.0 | 43.8 | 6.0 | M8 | 28.6 | 28.6 | 203-11 | 0.19 | 22 | 203-10 | 0.16 | PP | 203 | ||||||||||||||

| SAPP SBPP |

204-12 | 3/4 | 1 | 3 | 27/32 | 2 | 63/64 | 1 | 1/4 | 3/8 | 1 | 63/64 | 0.2756 | 5/16 | 1.2205 | 1.311 | SA | 204-12 | 0.9843 | SB | 204-12 | ||||||||||||

| SBPP | 204 | 20 | 25.4 | 98 | 76 | 32 | 9.5 | 3.0 | 50.5 | 7.0 | M8 | 31 | 33.3 | 204 | 0.23 | 25 | 204 | 0.23 | PP | 204 | |||||||||||||

| SAPP SBPP |

205-14 | 7/8 | 1 | 1/8 | 4 | 1/4 | 3 | 25/64 | 1 | 1/4 | 29/64 | 2 | 15/64 | 0.2953 | 3/8 | 1.2205 | 1.5 | SA | 205-14 | 1.0630 | SB | 205-14 | |||||||||||

| SAPP SBPP |

205 | 25 | 28.6 | 108 | 86 | 32 | 11.5 | 4.0 | 56.6 | 7.5 | M10 | 31 | 38.1 | 205 | 0.32 | 27 | 205 | 0.28 | PP | 205 | |||||||||||||

| 205-16 | 1 | 205-16 | 205-16 | ||||||||||||||||||||||||||||||

| SAPP SBPP |

206-18 | 1 | 1/8 | SA | 206-18 | SB | 206-18 | ||||||||||||||||||||||||||

| 206 | 30 | 1 | 5/16 | 4 | 19/32 | 3 | 47/64 | 1 | 1/2 | 29/64 | 2 | 39/64 | 0.3150 | 3/8 | 1.4055 | 1.7250 | 206 | 1.1811 | 206 | ||||||||||||||

| 206-19 | 1 | 3/16 | 33.3 | 117 | 95 | 38 | 11.5 | 4.0 | 66.3 | 8.0 | M10 | 35.7 | 44.5 | 206-19 | 0.50 | 30 | 206-19 | 0.47 | PP | 206 | |||||||||||||

| 206-20 | 1 | 1/4 | 206-20 | 206-20 | |||||||||||||||||||||||||||||